Optik cam inceltme-Optical lens thinning-Adelgazamiento de lentes ópticas-Optische Glasdünnung-Amincissement des verres optiques

Türkçe: Optik cam inceltme kavramı açısından camlar fiziksel güçle inceltilmez. Hammadde seçimine bağlı olarak camın kırma indisi değişir; daha yüksek indisli hammadde kullanıldığında cama gelen ışınlar daha fazla kırılır ve böylece aynı diyoptri gücünde daha ince camlar üretilebilir.

English: In terms of the concept of optical lens thinning, lenses are not thinned by physical force. Depending on the choice of raw material, the refractive index of the lens changes; when a higher index raw material is used, the light entering the lens is refracted more, and thus thinner lenses can be produced with the same diopter power.

Español:En cuanto al concepto de adelgazamiento de lentes ópticas, las lentes no se adelgazan mediante fuerza física. Según la elección de la materia prima, el índice de refracción del lente cambia; cuando se utiliza una materia prima de mayor índice, los rayos de luz que entran en el lente se refractan más, y de este modo se pueden producir lentes más delgadas con la misma potencia dióptrica.

Deutsch: Im Hinblick auf das Konzept der optischen Glasverdünnung werden Gläser nicht durch physische Kraft verdünnt. Abhängig von der Wahl des Rohmaterials ändert sich der Brechungsindex des Glases; wenn ein Rohmaterial mit höherem Index verwendet wird, werden die in das Glas eintretenden Lichtstrahlen stärker gebrochen, und so können bei gleicher Dioptrienstärke dünnere Gläser hergestellt werden.

Français: En ce qui concerne le concept d’amincissement des verres optiques, les verres ne sont pas amincis par la force physique. Selon le choix de la matière première, l’indice de réfraction du verre varie ; lorsqu’on utilise une matière première à indice plus élevé, les rayons lumineux entrant dans le verre sont davantage réfractés, et ainsi des verres plus fins peuvent être produits avec la même puissance en dioptries.

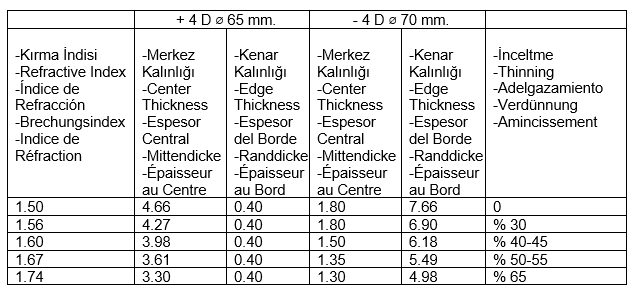

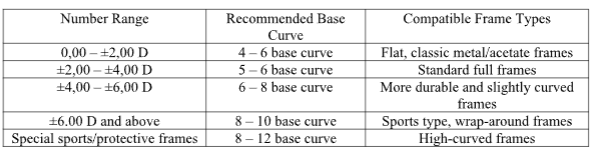

Tablo: +4 D ve -4 D cam örneğinde kırma indisine göre cam kalınlıklarında değişim. Bir cam üretici kataloğundan esinlenilmiştir.

Table: Variation in lens thicknesses according to refractive index in the example of +4 D and -4 D lenses. Inspired by a lens manufacturer’s catalog.

Tabla: Variación en los espesores de las lentes según el índice de refracción en el ejemplo de lentes de +4 D y -4 D. Inspirado en un catálogo de un fabricante de lentes.

Tabelle: Veränderung der Linsendicke je nach Brechungsindex am Beispiel von +4 D und -4 D Linsen. Inspiriert von einem Katalog eines Linsenherstellers.

Tableau: Variation de l’épaisseur des verres selon l’indice de réfraction dans l’exemple de verres de +4 D et -4 D. Inspiré d’un catalogue de fabricant de verres.

Lens Thinning Drawing – English (PDF)

CUSTOM OPTICAL LENS PARAMETERS

There have been negative feedbacks from our doctors regarding custom-made lenses: (https://www.todnet.org/html/todnet.asp?a=gozluk-camlari ).

To design progressive optical lenses custom-made, additional personal parameters that are not included in the standard prescription are required. Usually, an optician measures and provides these values to the lens company. The use of these parameters is aimed at increasing patient comfort. Despite the use of these parameters, if the patient complains, an individual assessment should be conducted.

Custom Lens Parameters

- Vertex distance

It is the distance between the corneal apex and the back surface of the lens.

- If a special value is not measured and provided, lens calculations are made assuming an approximate distance of 12-14 mm.

- If an actual measurement is not taken, especially in high diopters, the effective power will change.

- In custom design, the measured vertex distance is used to optimize the lens’ clear vision points.

- Pupil distances (right-left separate PD)

It is the distance between the centers of the pupils of both eyes, used to correctly align the optical centers of both eyes. It is more reliable to measure separately for right and left using a pupillometer device. Autorefractometers give the distance between both eyes, but do not measure individually for each eye, and are affected by head movements, so they should not be relied upon too much.

- If measured incorrectly, the center of the progressive channel shifts, causing the patient to experience blurriness or distortion, and may also lead to double vision or adaptation issues.

- In custom design, PD is perfectly adjusted, and the channels are aligned with the eye centers.

- Pupil height

- It is the vertical distance between the pupil and the lower edge of the frame.

- Very critical: because it determines where the reading area will be placed in progressive lenses.

- If measured incorrectly, the patient will not be able to focus comfortably on near or far vision.

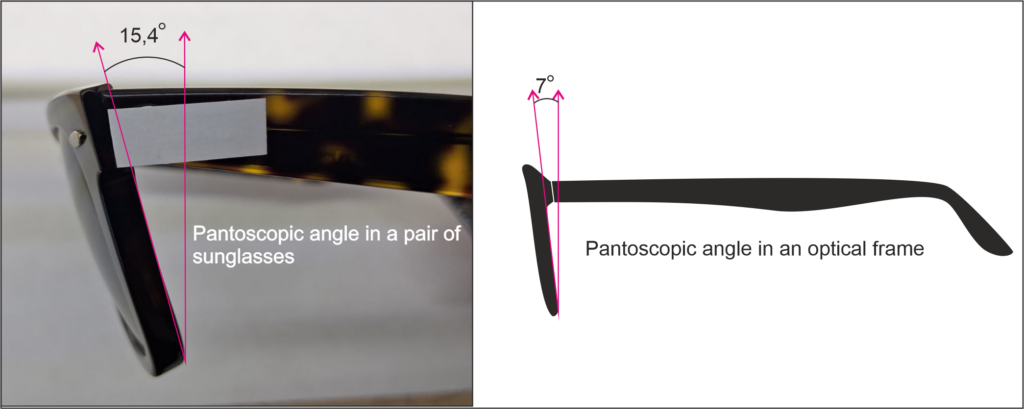

- Frame pantoscopic angle (See Image 1)

- It is the angle at which the frame tilts forward on the vertical axis.

- In optical frames on the market, it is usually between 8-12°.

- This angle changes the tilt of the light that reaches the optical center of the lens.

- If measured and accounted for, the progressive surface view lines sit more naturally.

- If this angle is not correctly taken into account, the optical fields of the lens may shift.

- Distance between the Eye Rotation Center (ERC) and the glass

This measurement is made with a special device and is not available in every optical store; it is usually found in optical stores that primarily offer high-end lenses. It is usually around 30-32 mm.

- It is the distance between the eye’s natural rotation center and the lens.

- It determines how the lens’ visual fields adapt to eye movements.

- It is important for sharpness during dynamic vision.

- If set incorrectly, blurriness increases, especially during side views.

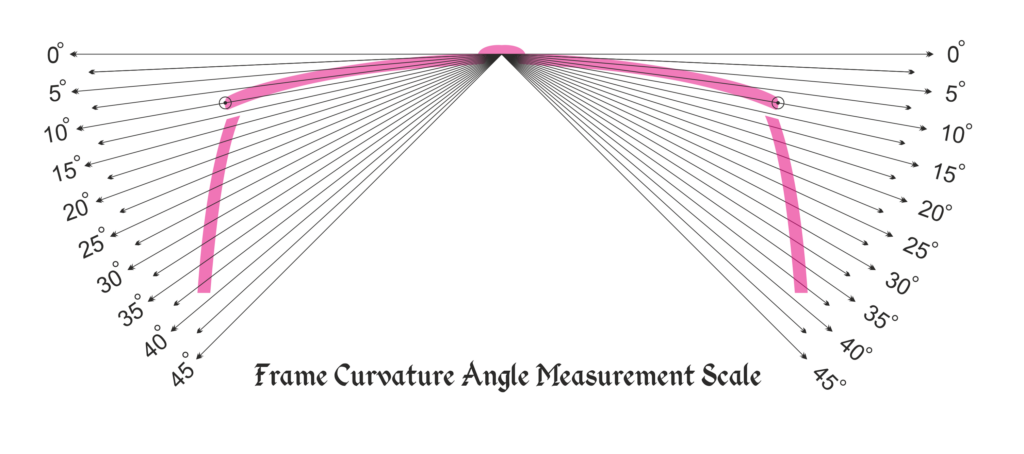

- Frame curvature angle (See Image 2)

- It is the angle at which the frame wraps around the face (in the horizontal plane).

- The curvature angle of the frame is especially considered in sports frames with designs that wrap around the eye area.

- It is higher in sports-type frames.

- This angle can cause astigmatism-like distortions on the lens surface.

- Design software takes this into account and performs surface compensation.

Conclusion

These are the basic parameters for the production of custom progressive lenses. When these parameters are accurately measured and communicated to the manufacturer, custom progressive lens designs become clearer and more comfortable. Additionally, some manufacturers include user habits and reading distance to make a more “personalized” design:

- “Reading distance habits and reading distance” are specifically for adjusting the near area to the individual, especially in presbyopes.

- In advanced “free-form” lenses, based on the user’s head-eye movement style, a wider corridor can be designed for those who turn their head more, and a different corridor design for those who make more eye movements.

- The dimensions of the frame (B measurement, shape factor) limit the corridor length.

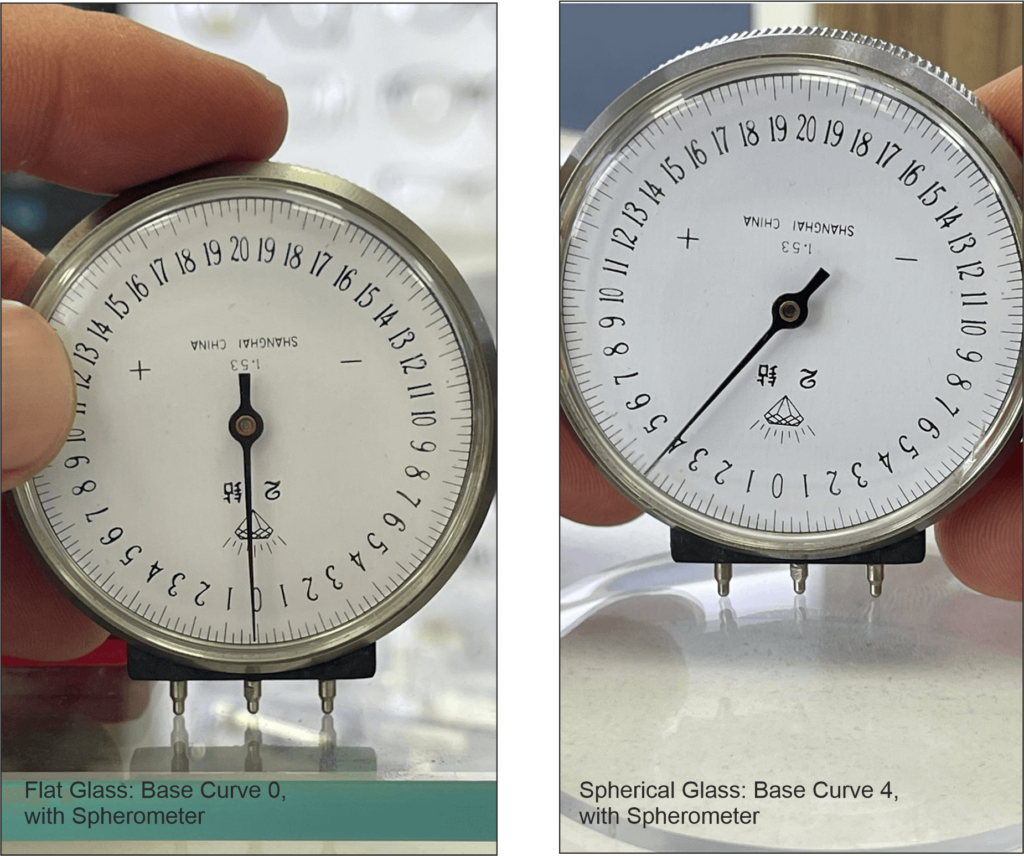

- The base curve of the frame (See Image 3) also plays a critical role in custom-made lenses, but is usually overlooked.

Why is the base curve important?

- If the curvature of the lens’ front surface is incompatible with the frame’s tilt, the lens will not fit the frame properly or may cause aesthetic issues.

- In custom-made lenses, the optical center and light refraction are calculated while considering the base curve. Incorrect base curve selection may increase the lens’ edge thickness and even degrade image quality.

- It is especially important in high-number or progressive lenses. This is because the manufacturer requires orders to be placed within the recommended base curve range.

Effect of the frame

- Sports frames, (wrapped) models, or highly curved frames require a special base curve.

- If the optician selects a frame that matches the “recommended base curve” range specified in the manufacturer’s lens catalog, the lens becomes more comfortable.

- In short: The compatibility between the frame’s base curve and the lens’ base curve is crucial for both assembly and optical comfort.

Explanation

- In low prescriptions (0–2 D), a base curve of 4–6 is usually preferred; flatter lenses are sufficient.

- In medium prescriptions (2–6 D), the base curve is slightly increased; this results in more balanced lens edge thickness.

- In high prescriptions (>6 D), higher base curves are required to prevent optical distortions and ensure aesthetic harmony.

- Sports / wrap-around frames already require higher base curves (8–12 base). It is more appropriate to use the manufacturer’s special “sport lens” series in this case.

In other words, if the frame selection is not compatible with the lens base curve, the lens assembly becomes more difficult, edge thickness increases, and optical distortions (aberrations) may occur.

Therefore, in custom progressive or high prescription lens orders, the optician must measure the frame’s base curve and report it to the manufacturer.

What is the Abbe Number?

In optics, the Abbe number (or Abbe value) is a measure that describes the chromatic separation property of a glass or optical material. This concept was developed by Ernst Abbe.

1. Definition

The Abbe number expresses how much a glass bends light of different wavelengths and to what extent it shows chromatic deviation.

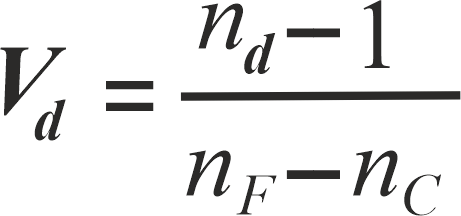

A commonly used formula is:

- nd: Refractive index for yellow mercury light (587.6 nm)

- nF: Refractive index for blue light (486.1 nm)

- nC: Refractive index for red light (656.3 nm)

- Vd: Abbe number

2. What does it mean??

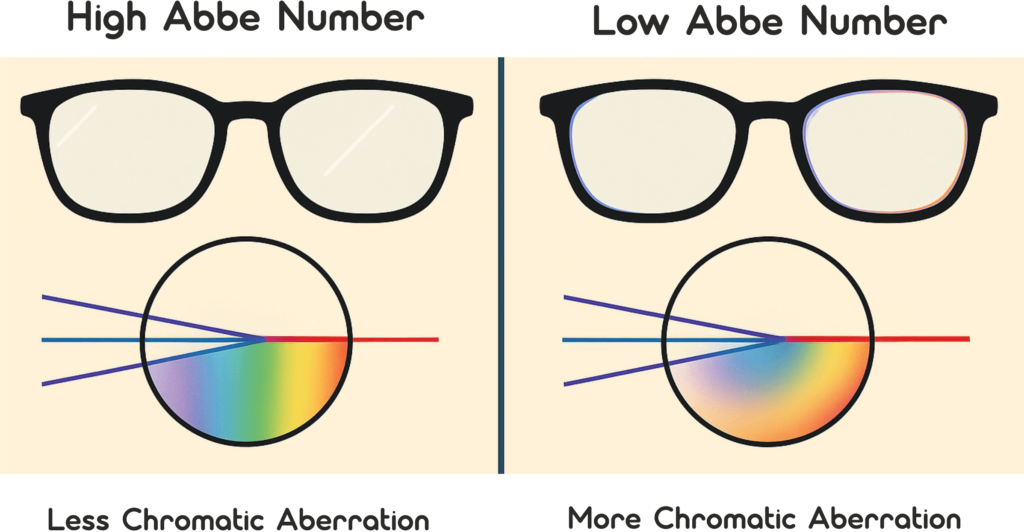

- High Abbe number → The glass shows little chromatic deviation → The image is sharper and color errors are minimal.

- Low Abbe number → The glass shows greater chromatic deviation → The image suffers from color fringing and edge distortion.

Samples

- Standard optical glasses: Abbe number around 50

- Plastic lenses: Typically around 30–40

- Special low-dispersion glasses: Around 60–70

3. Applications

- Eyeglass lenses

- Camera lenses

- Microscope and telescope optics

- Any optical system where minimizing chromatic aberration is required.

In short

- The Abbe number is a parameter that measures a glass’s tendency to separate light into colors.

In eyeglass lens design, glasses with high Abbe numbers are preferred to reduce color fringing, especially at the edges.

A simple diagram illustrates the effect of the Abbe number on eyeglass lenses and why it is important.